Hydraulic press machines are widely used in industrial fields to efficiently perform heavy processing tasks. With the application of a small force, the closed liquid in the hydraulic cylinder generates a large compression force. The hydraulic press machine was invented by Joseph Bramah in 1795 and uses a hydraulic lever instead of a mechanical lever. It features adjustable die space, stroke length, and applied pressure. These machines can be used to process a variety of materials including metal, plastic, wood, rubber, and others. Applications of a hydraulic press include metal forming, molding, bending, forging, sheet drawing, cold extrusion, straightening, flanging, stamping, and powder metallurgy. The hydraulic press machine is commonly used in the manufacturing of electrical appliances, automobile parts, rails, knives, and aircraft. This article provides a comprehensive overview of the definition, history, components, types, working principles, and applications of hydraulic press machines. A hydraulic press machine is a device that uses hydraulic fluid to generate a large amount of force on a small surface area for metal processing. Hydraulic presses range in size from small, such as relatively small bench press, to very large, such as 500-ton. Large hydraulic presses can be designed for low-tonnage applications, and small hydraulic presses can be designed for high-tonnage applications. It is mainly composed of a frame, base, power system, and control system. A hydraulic press uses a hydraulic cylinder to produce a compressive force and operates based on Pascal's law. The principles of hydraulic force inherently allow for customization, flexibility, and creative engineering. In the hydraulic press machine, the piston exerts pressure on the fluid, which in turn generates a mechanical force. The pressure generated by the piston is uniformly transmitted to all directions within the confined fluid, resulting in a uniform and smooth force being applied to the ram. The hydraulic press machine is widely used in the industrial field for metal forming, straightening, and crushing. It can generate a high tonnage of up to 10000 tons and is commonly used for pressing materials together or apart, forming metal parts, and bending and straightening materials. The hydraulic press machine operates based on Pascal's law, which states that when pressure is applied to a confined fluid, the pressure change occurs throughout the entire fluid. Hydraulic presses play a major role in the fabrication, assembly, and production of components for machinery and parts for commercial and industrial products. It is typically used in metalworking industries for sheet metal operations such as drawing, deep drawing, punching, and blanking. An H-Frame Hydraulic Press is a machine with a distinctive H-frame structure, equipped with a pressure cylinder, pump, and movable support. This type of hydraulic press is equipped with a manual pump and is commonly used for small-scale production. A C-Frame Hydraulic Press is designed with a C-shaped frame that offers better speed, accuracy, and guidance performance. This type of hydraulic press is more portable and is commonly used for fixing and assembling parts, disassembling components, or bearing installations. C frame hydraulic presses are available in single column (C frame) and double column (D frame) models. The Four-Column Hydraulic Press features two hydraulic cylinders and a central control system. The pressure and compression speed of this hydraulic press are adjustable, and it also has a semi-automatic circulation function. It's possible to adjust the blanking pressure and working pressure, and the four-column hydraulic press can exert a significant amount of force on the workpiece. The Roll-Frame Hydraulic Press is specifically designed for installing bearings, gears, and pulleys on axles and rollers. It can also be used for bearing calibration and pressing of shaft parts. Straightening Hydraulic Presses can be used to straighten straight shafts, plates, and large weldments. Hydraulic press technology has a rich history spanning thousands of years, and it focuses on fluid flow and control. It wasn't until the 18th century that the English inventor Joseph Brahma created the hydraulic press. He developed the hydraulic press machine based on Pascal's principle. Interestingly, he also invented the toilet, which has greatly improved our daily lives. In its early days, the hydraulic press machine-generated pressing force through a basic hydraulic cylinder. Today, the hydraulic press machine has been upgraded and is widely used in various applications, like agriculture and other fields. A hydraulic press machine can be selected to fit specific processes, materials, and scenarios. The basic structure of a hydraulic press machine consists of a frame, a working table, and a ram, and the key components work together to perform the pressing operation as follows: The hydraulic cylinder transforms the hydraulic system's fluid power into kinetic energy, which drives the ram. Oil is stored in an oil tank and is connected to the hydraulic cylinder's piston rod through pipes. When the hydraulic oil is transmitted to the piston rod, the hydraulic cylinder creates pressure to drive the ram and process the material. The hydraulic press uses a motor to power the oil pump, which converts mechanical force into pressure. A limit switch is used to adjust the height and thickness of the processed material, as well as to control the pressure applied to the workpiece by maintaining a set gap between the platens. The machine's relief valve releases any excess pressure in the pressed metal plate. The manual control valve allows for adjustment of the pressure applied by the slider on the workpiece. Finally, the electrical box controls the switches and joysticks of the machine through wiring and circuit connections. How a hydraulic press works? Now let us understand the fundamental principle of a hydraulic press here. Before we start, let's watch the video first: The hydraulic press machine operates based on the Pascal principle. It is composed of a hydraulic system including a hydraulic cylinder, piston, and hydraulic pipes. This press system typically has two hydraulic cylinders filled with hydraulic oil. The oil is typically stored in smaller servo cylinders. Pressure is generated when the piston connects with the servo cylinder, causing the hydraulic oil to flow into the larger hydraulic cylinder through the hydraulic pipe. The pressure applied to the larger cylinder and piston with a larger area pushes the hydraulic oil back to the servo cylinder. The force generated by the servo-hydraulic cylinder transfers to the hydraulic oil and results in a large force exerted by the master cylinder. The hydraulic system and ram then press, bend and form the materials. Although there are various types of hydraulic press machines, their working principles are similar. The hydraulic pump provides power to the machine, and the pressure and power of the hydraulic press can be adjusted by changing the type of pump used. Pumps can be manual, pneumatic, or electric, with electric and pneumatic pumps able to generate a more uniform force. When the pump starts, it pumps hydraulic oil into the hydraulic system, which then pressurizes. The reason that piston pumps are best suited for hydraulic presses is their ability to perform in high pressure hydraulic systems. Once the hydraulic oil enters the piston, it generates a large amount of pressure, driving the ram and punch to apply force to the workpiece. The hydraulic press machine can generate a great deal of energy with minimal force. Regular maintenance is essential for the optimal performance of a hydraulic press machine. Key maintenance tasks include: Modern hydraulic press machines are equipped with various safety features to protect operators and ensure safe operation: Hydraulic press machines are extensively used in the automotive industry for a wide range of applications, including: Hydraulic presses are commonly used in the aerospace industry: Many hydraulic presses are also used for: Manufacturers of heavy equipment, such as agricultural and construction machinery, use hydraulic press machines for: In the article, I have detailed the definition, history, components, types, working principles, and wide applications of hydraulic press machines. Understanding the working principles and different kinds of hydraulic press machines can help you make an informed decision about which machine is right for your needs. As a manufacturer with over 40 years of experience in producing press brakes, shearing machines, and laser cutting machines, my company, ADH Machine Tool, is dedicated to providing high-quality, high-performance machine tools and equipment. If you are looking for reliable metal processing solutions, contact our expert team. We are committed to offering you the best service and support. Visit our website now to learn more about our products and discover how our advanced equipment can enhance your production efficiency. Rubber & Tire Processing Machinery Rubber & Tire Processing Machinery is used to recycle waste tires and rubber to useful materials, like rubber granules and rubber powders. Rubber & Tire Processing Machinery,Rubber Powder Machine,Tire Processing Machinery,Scrap Rubber Crusher WUXI DEIICHEN MACHINERY PTY.,LTD , https://www.medicineprocessing.comI. Introduction

II. What Is A Hydraulic Press Machine?

1. What is an H frame hydraulic press machine?

2. What is a C frame hydraulic press machine?

3. What is four column hydraulic press machine?

4. What is a roll-frame hydraulic press machine?

5. What is a hydraulic straightening press machine?

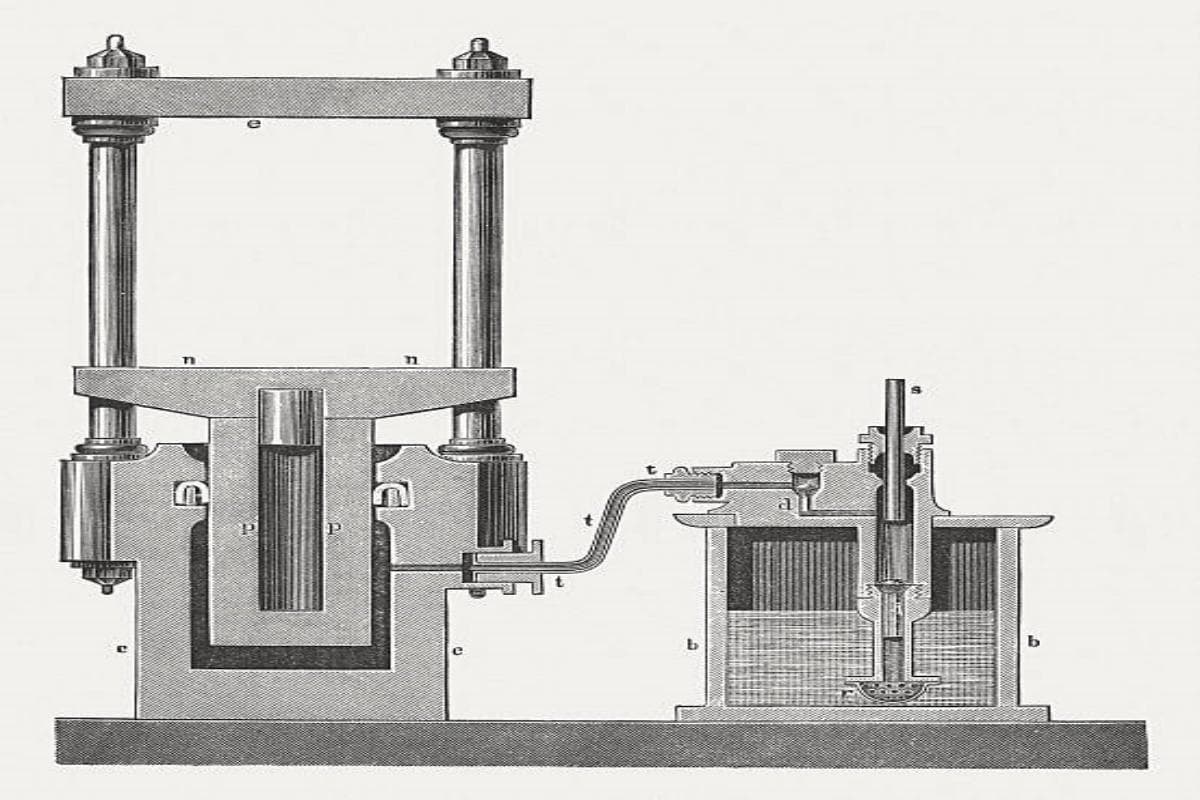

III. History of Hydraulic Press Machine

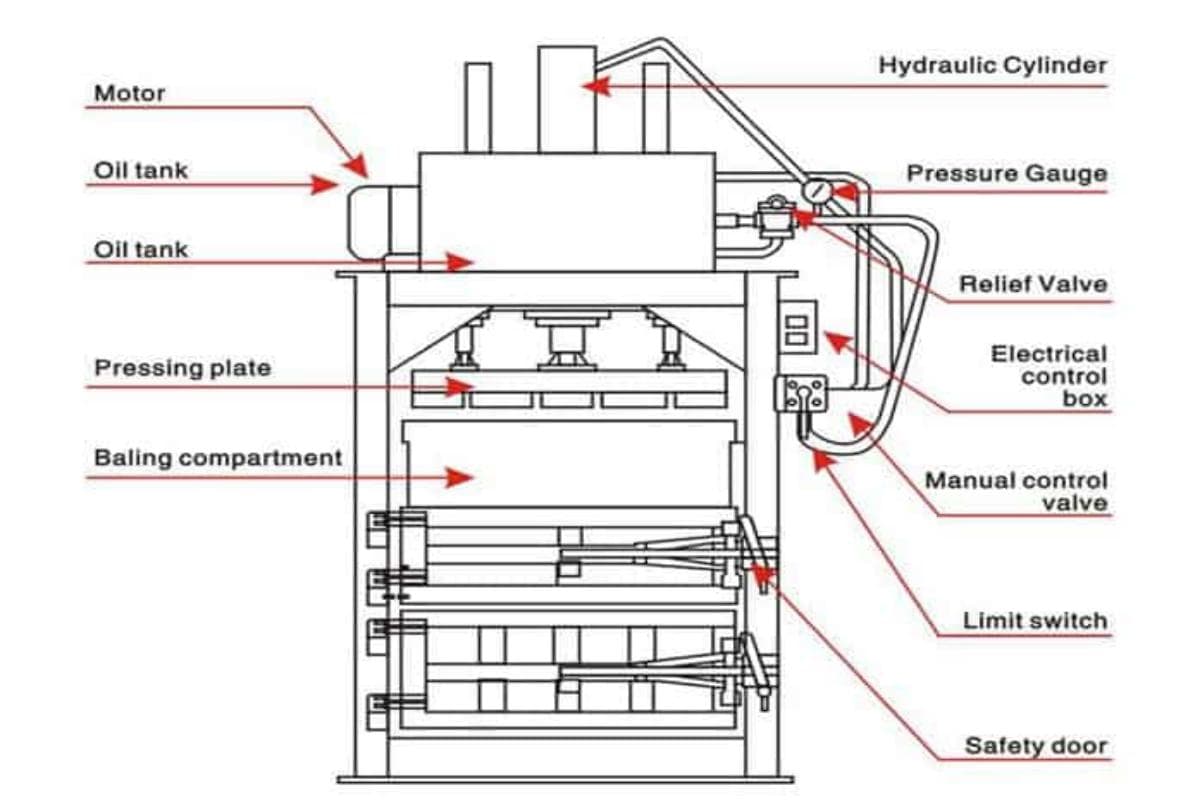

IV. Main Parts of Hydraulic Press Machine

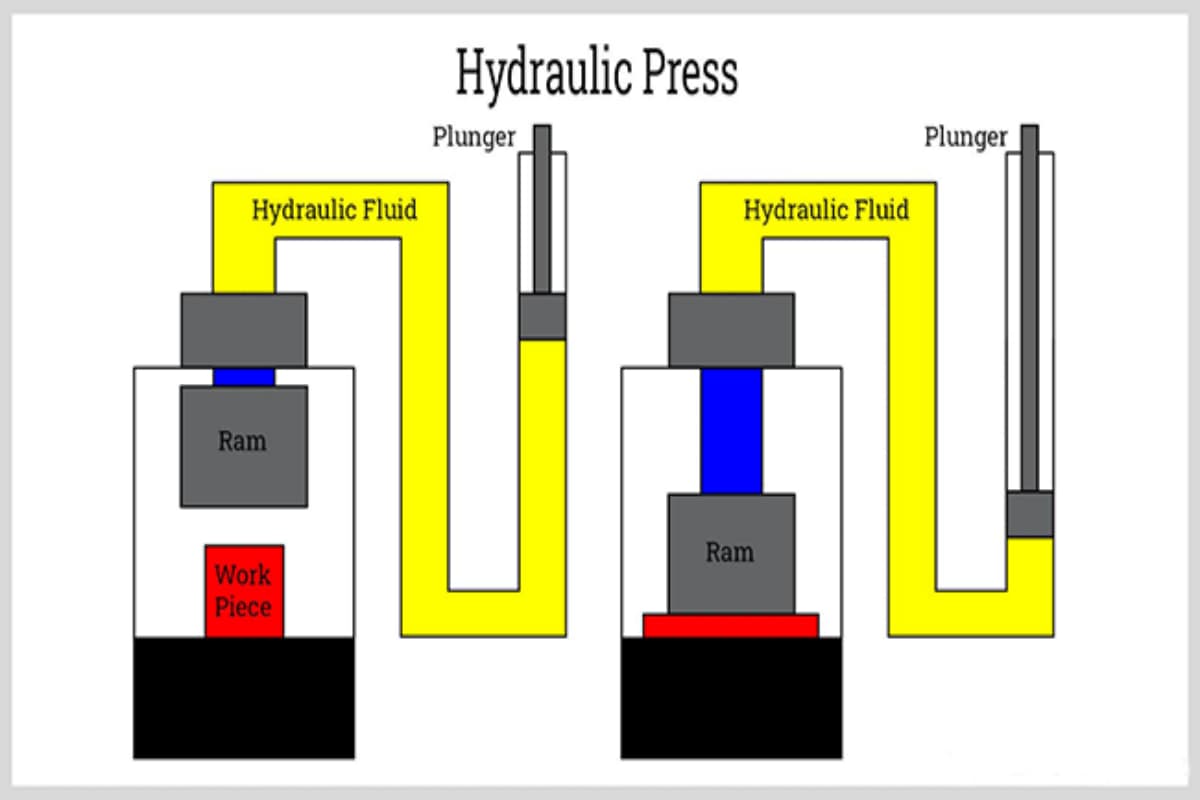

V. How Does A Hydraulic Press Machine Work?

VI. Maintenance and Care

VII. Safety Features

VIII. Application Examples

1. Automotive Industry:

2. Aerospace Industry:

3. Construction Industry:

4. Heavy Equipment Manufacturing:

IX. Conclusion